Yesterday I wrote here how Europe, particularly Germany, is driving out industry with sky-high energy prices.

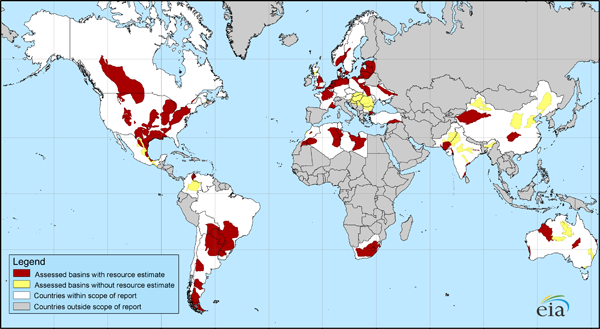

Will Europe deny its citizens a huge reserve of shale gas energy wealth? Looks that way. (Chart source: http://www.eia.gov/)

What follows is what sensible energy policy looks like.

Reader Mick J. left a comment on shale gas that deserves to be bumped up to a post (my emphasis):

================================

First, thank you for the site and the information it brings to us English speakers.

Perhaps this contrast published in March of this year will interest. How chemical manufacturer is returning to the US now that low gas prices resulting from Shale extraction has reduced prices.

Royal Dutch Shell announced this month that it chose a site near Pittsburgh for a facility to convert ethane from locally produced natural gas into ethylene and polyethylene. […] The planned ethane cracker would employ a few hundred workers.

It’s among nearly 30 chemical plants proposed in the U.S. in the next five years, […]. The projects would expand U.S. petrochemical capacity by 27% and employ 200,000 workers at the factories and related suppliers […]. As U.S. natural gas prices soared in the late 1990s, chemical makers moved overseas, laying off 140,000 employees,

…the U.S. has seen a natural gas boom in recent years, with producers using new drilling techniques to extract fuel from shale formations in Texas, Pennsylvania and other regions. U.S. natural gas prices, at slightly more than $2 per million British thermal units, are about 75% below Western Europe rates.

PricewaterhouseCoopers’ partner Robert Mc-Cutcheon estimates inexpensive natural gas could help U.S. manufacturers save $11.6 billion a year and create more than 500,000 jobs by 2025.”

==================================

Unless the European government wakes up from its climate-protection fantasy, there will be no need for anyone there to turn off the lights when leaving. They’ll be going out by themselves soon enough.

Also read: http://bit.ly/PhelimNYPOST (h/t Anthony Watts)

Oh, wow, the entirety of Northern Germany full of shale gas; great. Now we only need to get rid of ALL of the parties and found new ones (as ALL of them are against mining of any kind, or any other Gaia-disturbing activity).

[…] Ondertussen doet de EUSSR alles om onze nieuwe gigantische schaliegasvoorraden te vergeten. Amerika niet! 500.000 gasbanen in 2025. Romney of Obama maakt niet uit.H/T Pierre Gosselin!/*//>*/Aanverwante berichten:When Ideas Have […]

“Despite the expansion of wind power, Britain is becoming “increasingly dependent” on cheap coal to generate electricity, said the Renewable Energy Foundation.

It cited figures showing that coal-fired electricity increased by more than 30 per cent in the first three quarters of this year compared to the same period last year.

http://www.thegwpf.org/britains-new-dash-for-coal/

The Renewable Energy Foundation then goew on to say “coal is increasingly being used to generate electricity because gas is becoming much more expensive – and this strengthens the case for using wind power.”

So an increase in the use of wind power is causing an increase in the use of coal, therefore we need more wind power.

Further to Matt Damon’s self imposed delusion of the evils of fracking and all its claimed ills, meanwhile science and engineering move on and new methods bring both improved returns and better solutions for the resources used.

One process looking to be having good success and also improving yields uses Propane gel, it also removes the need for water and greatly reduces the need for propant such as sand, reducing the requirement by up to 75%. Also by using propane gel less binding occurs of other undesirable material thus leaving such in the ground.

“The firm has developed a Liquefied Petroleum Gas (LPG) or propane based gel that is as natural to a well as soil is to the earth. It’s dissolves into the formation hydrocarbons improving performance without using water.

LPG will burn of course so GASFRAC has developed a zero-oxygen, closed system and specialized equipment that protects worker safety, eliminates post-job cleanup and requires only minimal flaring that can be reduced to zero when installing the appropriate recapture facilities.

Without forcing water into the oil or gas laden rock opens the ability to quickly recover 100% of the fracturing fluid resulting in enhanced oil and gas recovery and longer sustained production. The LPG could be recaptured, reused or resold, a highly cost-effective benefit, especially for multi-stage horizontal wells.

GASFRAC is using your standard C3H8, a naturally occurring hydrocarbon that doesn’t damage the rock formation. In the gel form the material has low surface tension, low viscosity, low density, along with solubility within naturally occurring reservoir hydrocarbons – all of which when added together, create more effective fracture lengths, enabling higher initial and long term production of the well.

These properties have what GASFRAC claims are major advantages. The sand or proppant can be evenly distributed during pumping, thereby decreasing the chance of the proppant settling in odd inconvenient spots in the formations. The gel can generate a higher pay zone height throughout pumping and subsequent long-term production.

The waterless method increases initial production rates, helping establish production much sooner than traditional fracturing methods.

Sounds like an advertisement. Nearly so . . .

Except that the gel regains permeability with the stimulated hydrocarbons, with the ability to recover 100% of the fracturing fluids within days of stimulation. This creates economic and environmental benefits reducing clean-up, waste disposal and pre and post-job truck traffic, while creating higher initial production levels. It is a true win for producers and a win for the environment.

The technology isn’t yet fully proven. Still the firm has fracked over 1,300 wells in Canada and the US. The method was originally designed to improve the performance of low-pressure wells and has impressed those within the environmental arena. ”

Outlined here http://oilprice.com/Energy/Energy-General/A-New-Way-To-Fracture-Oil-and-Gas-Wells.html

Another process looks to replace the hydraulic method altogether. http://www.marketizer.com/news/pemex-signs-agreement-with-chimera-energy-corp-to-replace-hydraulic-fracturing-2842857.htm

Then there is this development. This method for cleaning the water used with this “sponge” solution looks interesting. The process is already in use for flood drain filtering and other situations where there is a need to remove oil products from water. The oil products collected by the sponge can then be used as a fuel.

“Smart Sponge, as Abtech’s product is called, is made out of extruded plastic in a secret process that makes the sponge highly oleophilic yet hydrophobic. That means the sponge refuses to soak up any water, while it loves oil so much that the sponge’s polymer molecules chemically bind with the hydrocarbon molecules. Sounds crazy, right? Once the Smart Sponge has soaked up some oil no amount of squeezing will get it back out.

Cleaning the frack water entails pumping it through a tank that contains loose pieces of Smart Sponge “popcorn.” It can handle 300 gallons a minute.

The oil locked up permanently inside, the used Smart Sponge can be disposed of in regular landfills — something you can’t do with a big jug of old motor oil.

But founder (and co-inventor) Glenn Rink says there’s no point in tossing away a perfectly good source of energy. A pound of Abtech sponge can soak up about three pounds of oil, meaning that once these sponges are fully engorged they are like blocks of fuel. Most generators that power oilfield equipment run on diesel. Abtech is developing generators that will get their power by burning oil-engorged Smart Sponges. The vision is to have a “closed-loop” water-processing system out in the oilfield that uses Smart Sponges to get the oil out of the water, then burns the sponges to power the system.”

http://www.forbes.com/sites/christopherhelman/2012/09/21/shale-gas-frackers-get-excited-about-a-new-sponge/?ss=innovation-science

Left wing idiot Matt Damon had to rewrite the story for his anti fracking film as, unfortunately, nobody found fracking induced contamination in groundwater.

http://www.breitbart.com/Big-Hollywood/2012/09/27/Matt-Damon-s-Anti-Fracking-Movie-Goes-Full-Conspiracy-Theory

[…] nitrogen fertilizer to plastics. Pierre Gosselin has a couple relevant posts at his No Tricks Zone. 500,000 New US Jobs By 2025 Thanks To Affordable Shale Gas – US Gas 75% Cheaper Than In Europe notes some of the industries moving back to the US or starting from scratch thanks to cheap natural […]